Doppstadt twin-shaft shredders are designed for a wide variety of applications and cover a wide range of areas and materials.

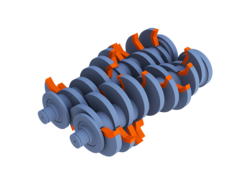

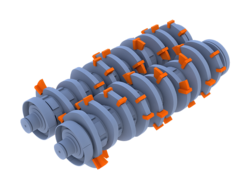

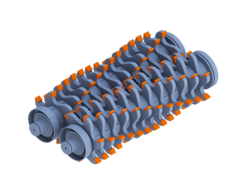

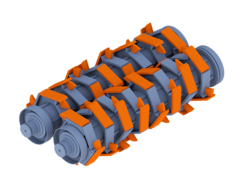

With the innovative quick-change system, the shredding unit can be easily adapted to your requirements. Depending on what you need to shred, our suitable shaft types, such as concrete shafts, paddle shafts, star shafts or metal shafts, offer you the ideal solution depending on the machine model:

- Construction & Demolition waste

- Commercial waste

- Rubber & Scrap tyres

- Natural & Waste wood

- Wooden rail sleepers

- Trunk wood

- Green waste

- Paper & Cardboard

- CFRP & GRP waste

- Automotive & Aluminium scrap

Note: Coreline products are currently offered exclusively on international markets and are not available for orders from Germany.

- Video - Commercial & Mixed construction waste

- Video - Construction rubble & Waste wood

- Construction & Demolition waste

- Commercial waste

- Tyres

- Scrap

- Waste wood

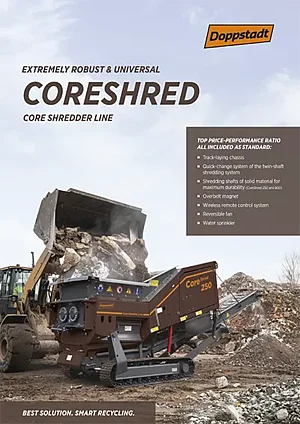

To ensure that nothing is left to be desired, we have calculated carefully for you and equipped our Core Shredder Line so that almost everything is included as standard. With all CoreShred models, you can start immediately from day one and still remain flexible if the material requirements change.

We also have exactly the right machine for every performance requirement. The compact CoreShred 250 is the right choice for smaller processing quantities, the CoreShred 800 for the medium class and the CoreShred 900 for the high-performance class.

To reliably remove ferrous metals and maximize yield, all CoreShredder models are equipped with a height-adjustable permanent overbelt magnet.

Hydraulically adjustable and self-cleaning, the fan ensures efficient motor cooling and internal circulation.

For optimum maneuverability on any terrain and easy loading by low-loader truck, with the CoreShred 250 via hook lift. All chassis are also optionally available on steel tracks with rubber pads.

Water spraying effectively reduces the amount of dust generated when the shredded material is discharged.

With the quick-change system, the machine can be adapted to a different material requirement in the shortest possible time. Depending on the CoreShredder model, corresponding interchangeable cassettes with concrete/paddle/metal or star shaft pairs are available for this purpose and offer high machine availability in daily use.

This unit consists of a large-volume feed hopper, the twin-shaft shredding system with shafts made of solid material (CoreShred 250 and 800) for optimum durability and mechanically or hydraulically adjustable counter combs for setting the final grain sizes.

The folding hopper, which can be adjusted up to 180°, picks up large quantities of material and gradually optimises the material feed at the touch of a button.

This is because the powerful VOLVO PENTA motors perform reliably with low consumption and maximum efficiency in all CoreShredder models and are also available in emission levels V, Tier IVf and EIIIA.

With optimally preset rotation of the shredding shafts and via wireless remote control system, the shredders are very easy to control and manoeuvre in the field.

The more precisely the tool matches the material, the better the work result. We have developed a cassette-type quick-change system for the shredding shaft pairs so that the changeover can be carried out as quickly and efficiently as possible.

The shafts in the CoreShred 250 and 800 are made of solid material and are manufactured from highly wear-resistant steel with a special surface hardening process. The shaft discs and shredding tools are welded onto this base body. The shape and arrangement of the discs and the shaft blades play a key role in determining which material can be shredded.

ALWAYS EXACTLY THE RIGHT SOLUTION.

To adjust the final grain sizes, the counter combs in the shredding unit can be opened or closed mechanically or hydraulically, depending on the model.

This allows the operator to adjust both the throughput of the shredder and the quality of the material treatment to customer requirements.

WE BRING IT TO THE POINT.

We are convinced that these arguments and solutions from Doppstadt will support you in your recycling and processing challenges.

- Competitively superior range of applications

- Extensive standard equipment

- Innovative quick-change shaft system

- International sales and service network

- Best price-performance ratio in the branch

Rollout and availability

The new Doppstadt product line Core Line starts on May 1, 2025 with the models of the Core Shredder Line series:

the CoreShred 250, CoreShred 800 and CoreShred 900 twin-shaft shredders.

These products will be offered internationally, but not in the German market.

In the UK and Spain, sales of the CoreShred 250 model will begin on July 1, 2025.