AK 560

Ihr Kontakt

Doppstadt Umwelttechnik GmbHSteinbrink 13

42555 Velbert

Deutschland

Phone: +49 2052-889-344

Email: used(at)doppstadt.de

URL: doppstadt.de

Specifications

| Price | 149,000 € |

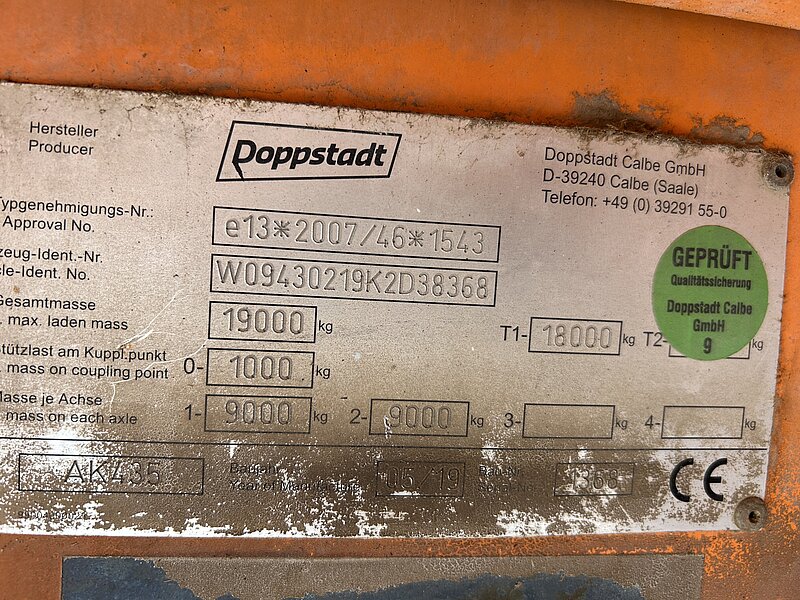

| Manufacturer | Doppstadt |

| Model | AK 560 |

| Construction number | 1368 |

| Procedures | Grinder |

| Year of construction | 05/2019 |

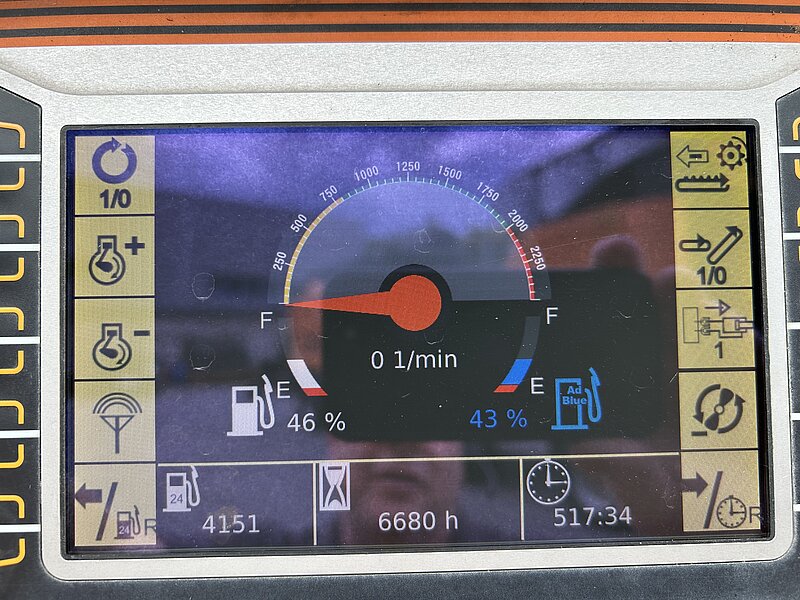

| Operating hours | 6680 |

| Location | D-42489 Wülfrath |

Product information

Equipment:

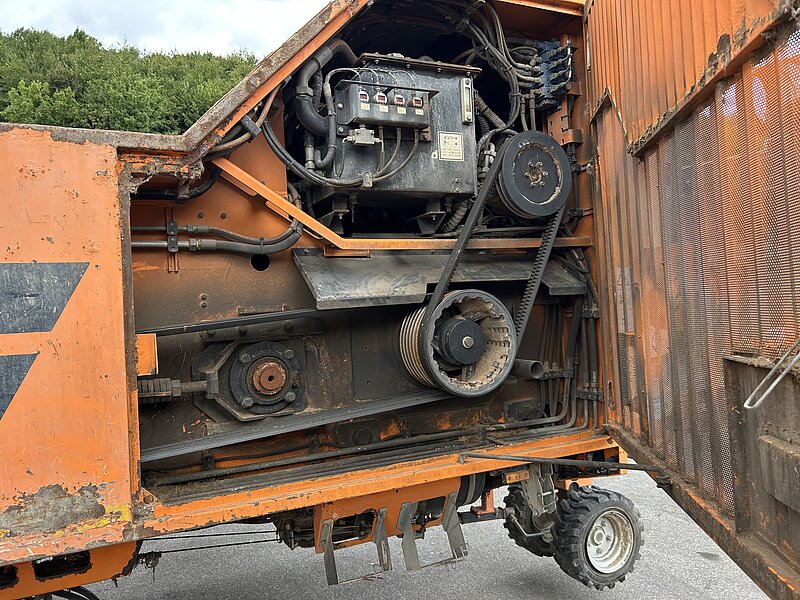

Standard equipment AK 560 Eco-Power:

- Central-axle trailer chassis with 2 axles, licence for 80 km/h on public roads

- Brake system with ABS brake and lighting acc. to EC directive

- 50 mm EC drawbar eye, incl. drawbar coupling

- Tyres 385/65 R22,5

- Hydraulically adjustable jack-leg

- Splashguard (inside and at side of fenders)

- Permissible total weight 19,000 kg

- Mercedes/MTU Diesel engine 6R1300, 390 kW at 2,000 rpm, complies with the emission standard EUROMOT IV

- Load-sensing material feeding incl. automatic scraper floor reverse

- Fuel tank 450 litres

- Infeed drum: length 1,690 mm, diameter 510 mm, with fitted tooth segments

- Four-row flail drum with 36 free-swinging cast steel flail holders and replaceable flail tips

- Standard equipment: flail tips “carbide-sprayed”

- Central lubrication points

- Electric pump for control of the cylinder functions (e. g. rear basket open/close and support up/down, folding of the rear conveyor, release of the hydraulic self-propelled drive) at engine standstill

- 24 Volt electrical control

- Additional control box at rear part of the machine

- Hydraulically opening fine-shredding basket (mesh sizes between 30 and 280 mm, grading on request) incl. hood

- Scraper floor with 32 scraper bars

- Radio remote control compl.

- Preparation for hydraulic self-propelled drive

- Acoustic start indication

- Paint: RAL 2011 orange

Additional Equipment:

- Hydraulic self-propell

- Drawbar extension 400 mm

- Fuel tank 600 l

- Additional hydraulic connection 20 l/min

- Flail tips "Bear claw"

- fine-shredding basket

- Baffle plate with smash bar

- Rear conveyor 4 m

- Separate drive for feed-in roller and scraper floor “Twin Drive”

- Reinforcing panels at the feeding hopper

Delivery by arrangement